Solutions

From design to finished product: all our solutions for your electronic systems

We accompany you in the design, inspection and test phase

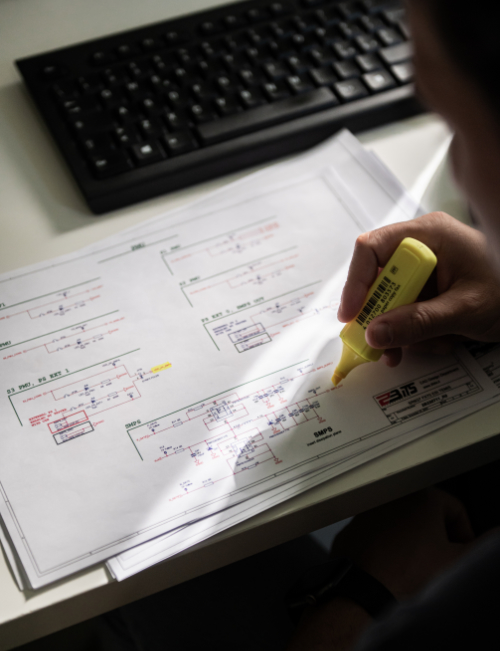

Hardware Design

According to customer specifications or starting from an existing design, we develop prototypes and custom boards for both the semiconductors and the industrial and medical world.

read more

In particular, we create diagrams of:

-

Power Supplies;

-

Complex embedded systems;

-

Systems for home automation and automotive;

-

Cards for testing and reliability of semiconductor devices;

-

Functional testing systems;

-

Cards for ATE, reliability, validation and EMC testing for different platforms (J750, V93K, ETS364, T2000, Fusion, UBTS, ART, ETOS).

Software Design

Thanks to our know-how, we design entire software architectures or integrate existing ones. We work with machine language code, up to complex systems and graphical interfaces.

Our engineers create applications based on traditional languages such as C/C++, modern ones such as Python, Rust, Java and they use frameworks to manage Machine Learning on the edge, creating software to integrate advanced connectivity into the boards, such as Bluetooth LowEnergy, WiFi, NFC, Matter, Ethernet and much more.

read more

For the semiconductor world, we also directly develop or we support the customer with drafting test programs for:

- ATE Systems (ETS364/88, T2K, V93K, FUSION, DIAMOND)

- Reliability systems (ETOS, ART200, UBTS, smART)

2D-3D layout drawing

Our CAD designers work on 2D and 3D layouts with the most famous suites in the industry.

The ten-year experience of the CAD team members ensures high quality while respecting the physical and electronic characteristics of the devices, creating board layouts with even high complexity.

read more

We create for you:

- drawing and layout of boards from 2 up to 40 layers, rigid flex;

- pre and post layout simulations, single-ended and differential controlled impedances;

- testing on layouts for RF, EMC;

- 3D simulations.

2D-3D mechanical drawing

The mechanical designers team supports the customer by carrying out simulations to ensure compatibility between the electronic board and the mechanical assembly, as well as to create real mechanical and structural parts of the system.

We use the best 3D mechanical software and the new generation of wire and resin 3D printers.

read more

We create:

- Particular supports;

- Supplied accessories;

- Custom containers ;

- Prototypes in resin and/or other materials;

- Small series through state-of-the-art machinery, in a short time.

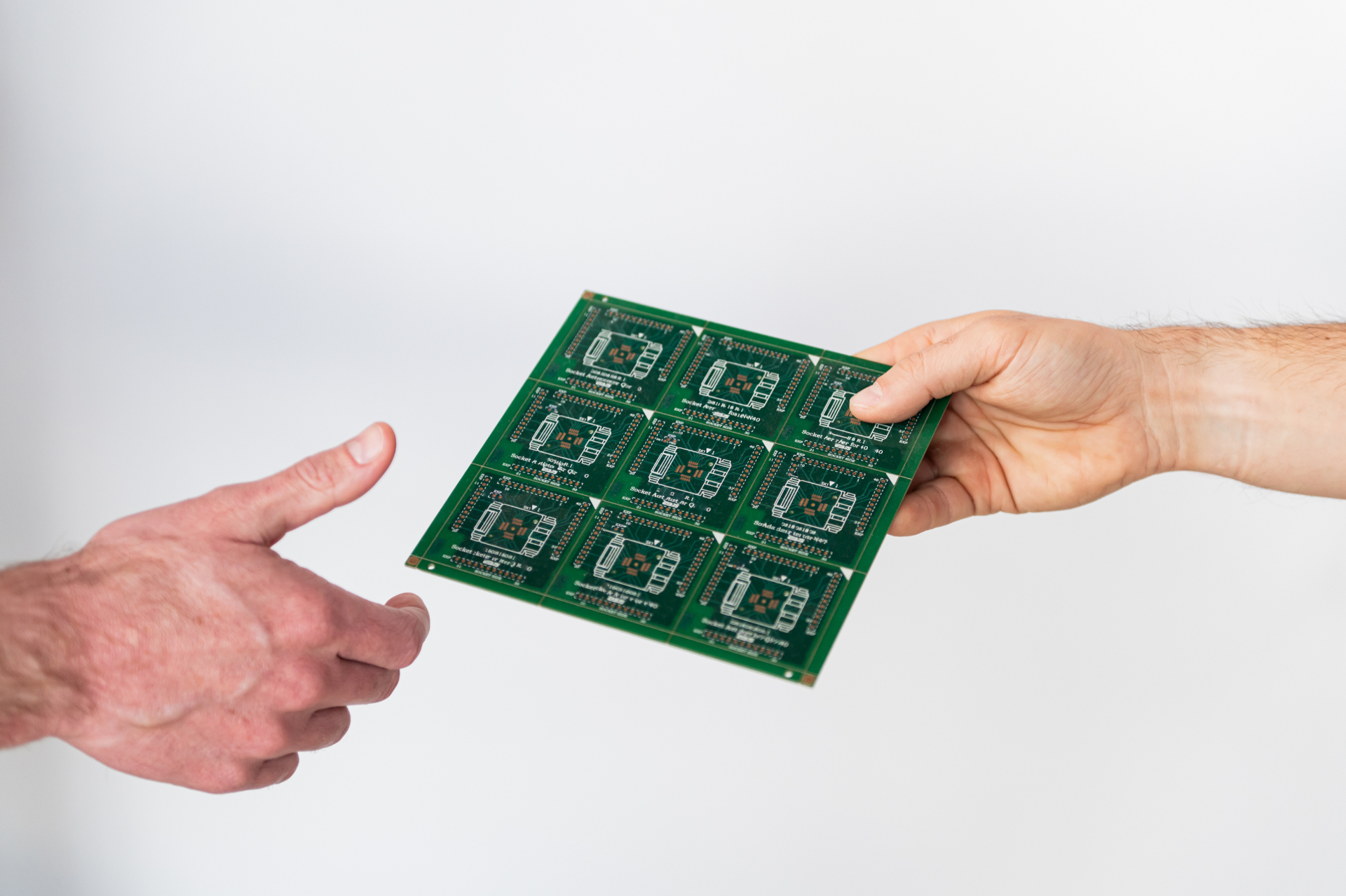

Production and assembly of PCBs with SMT/PTH

We have an automated SMT assembly line, convection and steam phase furnaces and operate in accordance with RoHS directives, using both Sn/Pb alloys and mixed technologies.

We guarantee quality and fast response times for prototyping and mass production.

read more

In our PTH Assembly Department:

- We complete the assembly process in a traditional way or through a paste-in-hole process;

- We carry out inspections on assembled products (with AOI and X-ray machines) and washing before delivery;

- We have automatic conformal coating systems for resin plating of boards.

We are IPC certified

IPC is the globally recognised standard that establishes the rules to guarantee the quality of electronic boards, from design to finished product. 2BiTS with IPC-A-610 certification provides a quality of assembly and service that complies with the highest standards, in class 3.

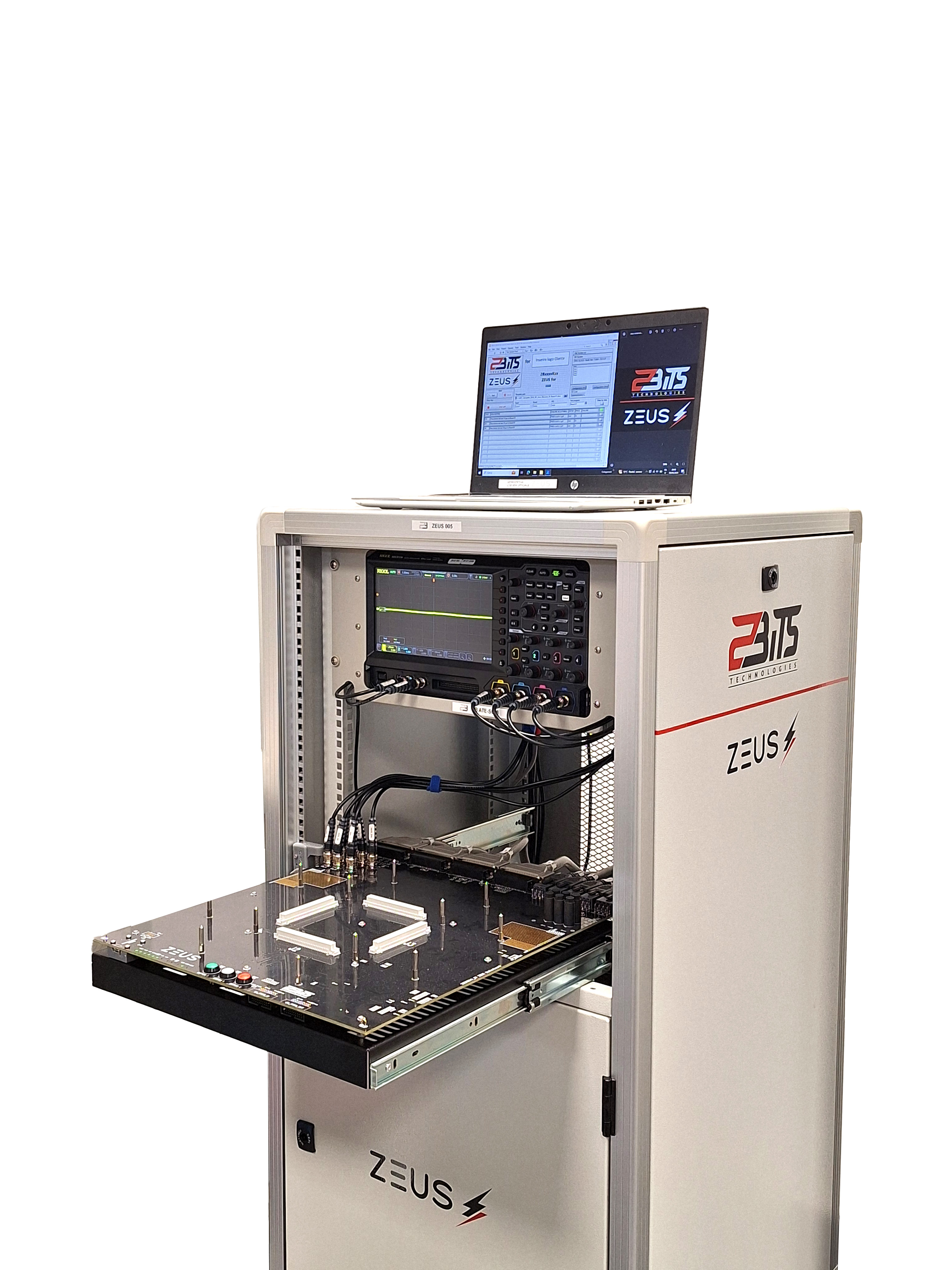

Automated functional tests

We develop testing programs based on our interface boards, to test both semiconductors and entire embedded systems during the final phase of production.

We carry out tests for you with ATE systems (Accotest, Teradyne, Agilent, Eagle) and perform reliability tests (ETOS, ARES, ART200, UBTS etc.); thanks to our internal Testing House, we provide a turnkey solution for semiconductor tests, to carry out engineering tests in Tri-Temp.

read more

- We design test systems with fixed and mobile probes for continuity and functional tests;

- We create customized systems to directly test the product online, even simulating extreme weather conditions;

- We write firmware for different families of microcontrollers or FPGA devices and custom software for any application.

Rework, modifications and repairs

We offer our customers complete support in troubleshooting and together we study customized solutions to improve products.

In our rework clinic we perform rework and replacements in manual or semi-automatic mode. The final X-Ray inspection ensures the quality and conformity of the welds.

read more

We can guarantee support for almost all types of products, including:

- Devices with miniature packages

- Devices with ultra-fine pitch (microBGA/TQFP/QFN/CSP up to 0.3mm);

- Wafer Scale Package.

2Bits s.r.l. Partita IVA 03705390981 Rea BS-556200 All copyrights reserved © 2024 Designed by Lafil Design